SCHIMMER ENERGY

Schimmer Energy is the manufacturing core of Yash Group with a mission is to become one of the most respected single window hydro solution providers around the world. Backed with precise expertise and proven technology coupled with execution excellence Schimmer Energy has the credence to deliver world class water to wire solutions.

As an organisation, we are a full line supplier of Electromechanical Equipment & Services for Small & Medium Hydropower Projects and aftermarket service for the existing power plants.

We provide Turnkey Hydropower Solutions – with cohesive integration of design, manufacturing, execution and service support. With our incessant focus on quality and total customer satisfaction, we have set new benchmarks in ‘implementation finesse’ that have translated into sustainable benefits for our customers

Schimmer Energy has exclusive tie-ups with Italian companies to offer European excellence by manufacturing in-house major critical components like turbines, runners, valves, governors etc. These strategic joint ventures gives Yash Group the world class design and technological advantage in small and medium hydro power plants. Topped with Indian business insights, operational advantages and customised deliverables packaged at value added pricing.

CONCEPT TO COMMISSIONING EXPERTISE

Dedicated customized solutions based on specific requirement

State of the art manufacturing facilities coupled with stringent quality control meeting international standards

Services to ensure reliability, efficient operation and long term healthiness of plant.

Backed by proven technologies from leading European partners for providing water to wire solutions.

State-of-the-art manufacturing facilities coupled with stringent quality control meeting international standards

PRODUCT OVERVIEW

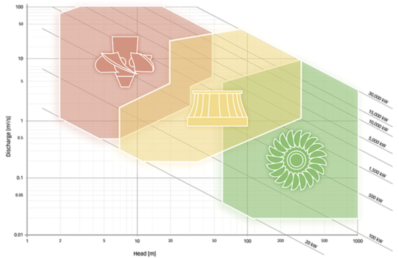

Schimmer Energy has the expertise to offer complete range of Hydro-turbines packages (Pelton, Francis, Kaplan, Axial flow units) upto head range of 1,000 meter and with discharge of 100 m3/sec. These turbines are designed for efficient & high performance with long term serviceability support.

PRODUCT PROFILE

PELTON TURBINE

- Nozzle configuration from 1 Jet up to 6 Jets

- Unit capacity up to 30 MW

- Operating Heads up to 1000 meters

- Runners in forged/cast construction

FRANCIS TURBINE

- Horizontal/Vertical configuration

- Unit capacity up to 30 MW

- Operating Heads up to 450 meters

- Runners in forged/cast construction

- Mechanical & Electrical BoP and auxiliaries offered

- SCADA, Automation and Communication System

- In house Control, Protection and Metering Panels

- Transportation, Erection and Commissioning

KAPLAN TURBINE

- Horizontal/Vertical configuration

- Unit capacity up to 15 MW

- Operating Heads up to 45 meters

- Multi Runner blade option

- Semi/Full Kaplan option

RELIABLE TECHNOLOGY

The turbine hydraulic design uses latest technologies and high end developed software including CAD-CAM and CFD software for efficient flow characteristics.

Detailed transient study is carried out to determine water hammer characteristics by latest Software ensuring optimum and safe operation.

KEY PROJECTS OF SCHIMMER ENERGY

ERECTION AT JEULI GAD, NEPAL, 1 x 1 MW, Horizontal Francis

LOWER TADI KHOLA, NEPAL, 2 x 2.5 MW, Horizontal Francis

LOWER CHHOTE KHOLA, NEPAL, 2 x 0.5 MW, 2 Jet Horizontal Pelton

UPPER RAWA KHOLA, NEPAL, 2 x 1.5 MW, 3 Jet Horizontal Pelton